Our Manufacturing Facilities

We have sub-contracted Dyeing/Printing units and 10 automatic rapier looms to weave wide range textured fabrics.

Office & Production House

Spread across 26,000 sq/ft (2,400 sq/meter), our production facility is equipped with 30 high-speed stitching machines, a shrink wrap machine to keep cartons safe and dry, and 4 steam ironing tables — ensuring careful finishing and high-caliber output for every product. "Inside Our Cutting, Checking, Finishes and packing — Where Quality Meets Craftsmanship."

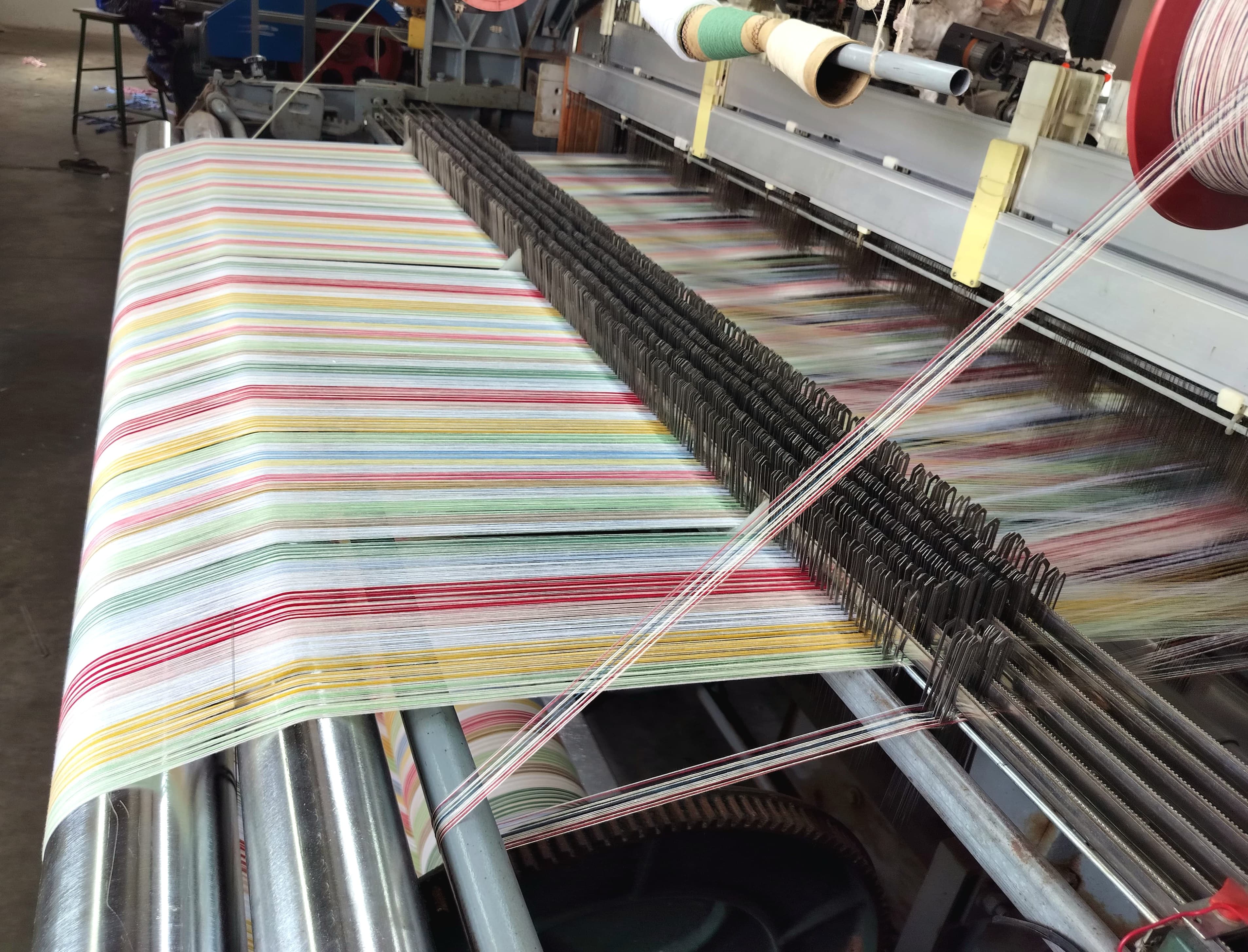

Weaving Factory

With a working area of 6,500 sq/ft (600 sq/meter), our weaving factory houses 10 automatic looms — delivering intricate, high-caliber fabrics that bring your creative visions to life.

Dyeing & Printing

We collaborate with our trusted partner, SM Dyeing Works, for rich colors and accurate patterns. Strict quality control ensures exceptional finishes that align with your design requirements.

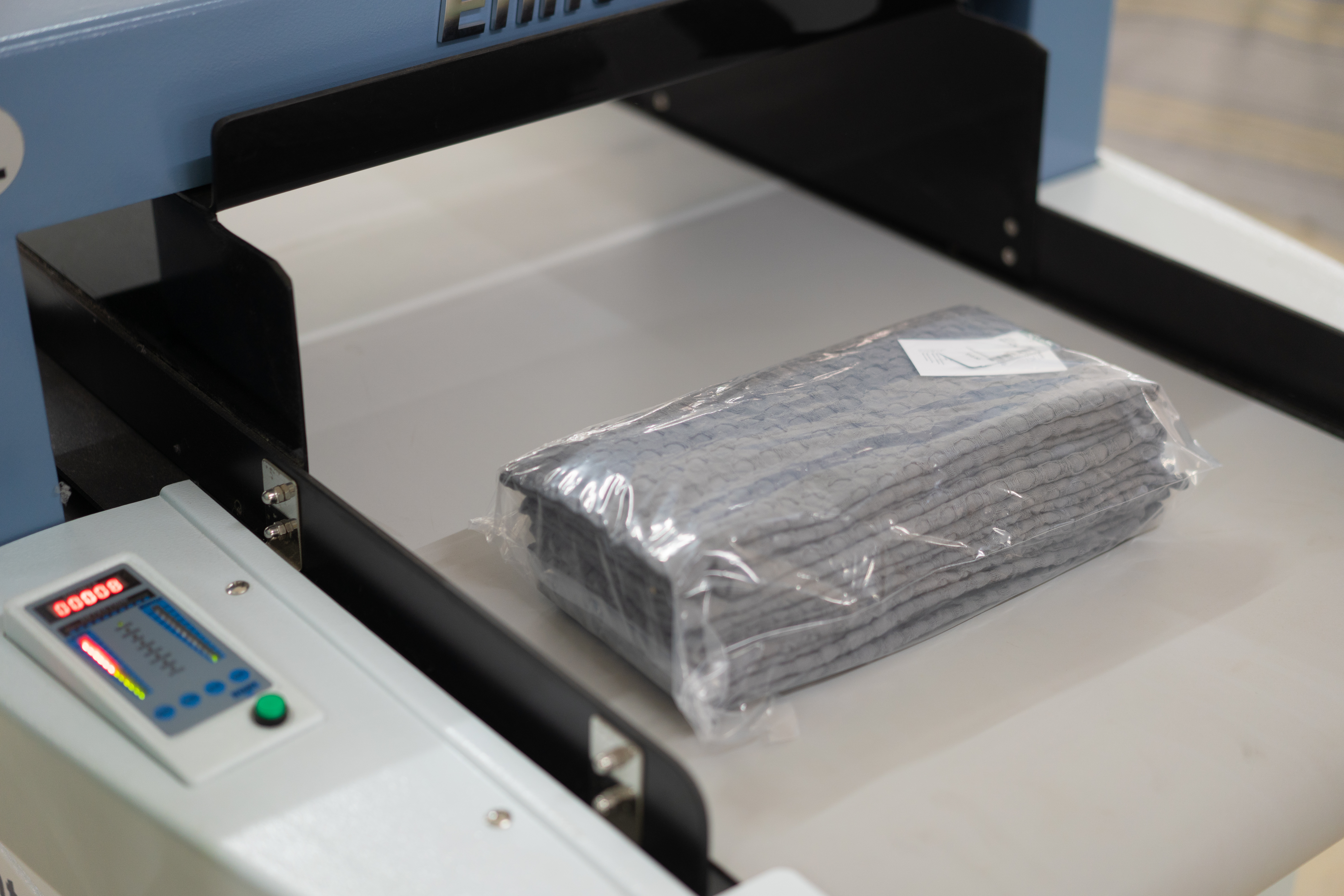

Needle Metal Detector HD760CE-20

We use the HD760CE-20 Needle Metal Detector to identify even tiny metal contaminants (1.2 mm steel), ensuring every product meets the highest safety and quality standards.

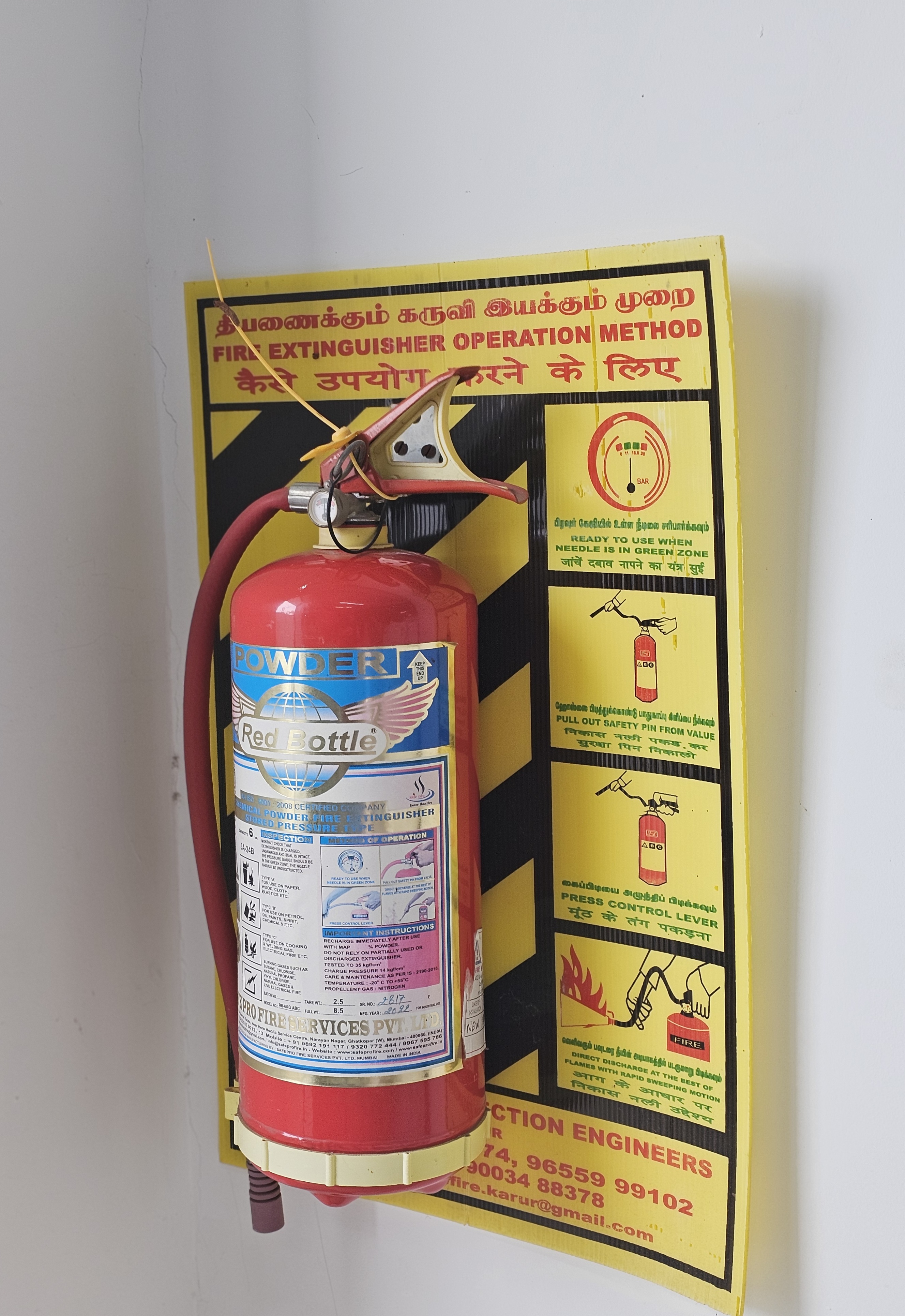

Safety and Lockers

Safety is our top priority. Our building is equipped with CCTV cameras, smoke detectors, fire pipes, communication lines, extinguishers, and clear safety signage throughout. Each team member is provided a personal locker for securely storing their belongings.

Final Packaging Line

We ensure secure and moisture-resistant packaging using high-quality 5-ply or 7-ply corrugated carton boxes. Each product is individually polybag-packed and carefully labeled. Cartons are sealed with strong straps and tapes to prevent damage during transit. Custom branding and pallet packing options are also available as per buyer requirements.

Certifications

Our Production House and Weaving Unit are proudly certified with GOTS, GRS, and OCS standards. These globally recognized certifications ensure sustainable sourcing, ethical manufacturing, and verified organic or recycled content. They reflect our commitment to quality, transparency, and responsible production.